In the realm of heavy-duty industries, the reliability of systems often hinges on the ability to maintain a secure and tight environment. Vacuum connectors play a crucial role in ensuring this, serving as vital components in manufacturing applications where extreme vacuum conditions are necessary. From production processes to scientific facilities, the need for reliable sealing solutions has never been higher, as businesses strive to boost efficiency and protection in their operations.

Such specialized sealing devices facilitate the connection of various vacuum elements, ensuring that systems can withstand the challenges posed by decreased pressure and intensive requirements. As sectors continue to evolve, the exploration of vacuum flange applications reveals a fascinating intersection of technology and creativity, emphasizing their importance in sectors covering chip manufacturing to pharmaceuticals. Understanding the role and functionality of vacuum flanges is essential to recognizing their influence in the current industrial landscape.

Types of Vacuum Seals

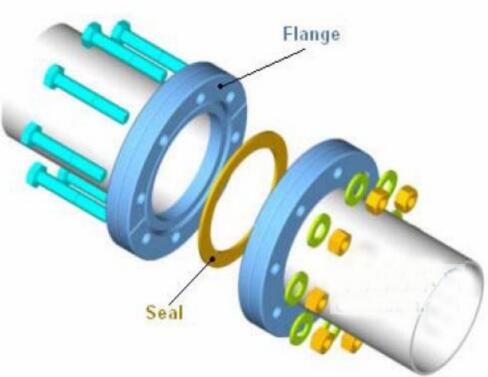

Seals are essential parts used to create sealed connections in various manufacturing applications. Common types of vacuum flanges comprise ANSI, Klein-type, and CF flanges, each designed to meet particular requirements. ANSI flanges are typically used in low to medium vacuum settings, providing a reliable joint with relatively easy assembly and disassembly. They are ideal for systems that require recurrent access for upkeep or alteration.

KF flanges, also known as Klein Flanges, are designed for high vacuum contexts and have a quick-connect design. This allows for fast assembly and disassembly, making them appropriate for applications where rapid changes are necessary. KF flanges use a rubber O-ring to ensure a tight seal, which contributes to their efficiency in maintaining low pressure environments. These flanges are widely used in research facilities.

CF flanges, or Conflat flanges, deliver the highest vacuum performance and are designed for very high vacuum contexts. They are machined to precise standards and rely on a knife-edge design that squeezes against the sealing surface, resulting in an superior seal. CF flanges require the use of metallic gaskets, commonly made of copper or aluminum, and are favored in environments where optimal vacuum integrity is critical, such as in chip manufacturing and particle accelerators.

Uses in Major Industries

Pressure flanges play a vital role in various heavy sectors where the management of pressure and containment of gases and liquids are essential. In the manufacturing sector, these flanges are widely used in applications including vacuum metalizing, where metal coatings are applied to surfaces in a vacuum environment. This application not only enhances the durability of products but also boosts their aesthetic appeal. The reliability of vacuum flanges in maintaining airtight seals allows for smooth operations, minimizing the risk of contamination during the manufacturing process.

In the aviation industry, vacuum flanges are integral for ensuring the integrity of systems that operate under extreme conditions. Components such as satellite systems, spacecraft, and testing chambers rely on vacuum technology to function correctly. The ability of vacuum flanges to withstand high pressures and temperatures is essential in preventing leaks that could compromise the performance and safety of aerospace applications. This guarantees that essential components are tested and function under precise conditions, ensuring mission success.

The chemical processing industry also gains significantly from the application of vacuum flanges. In processes like distillation, evaporation, and reaction, maintaining a consistent vacuum is vital for the efficiency and safety of chemical reactions. Vacuum flanges provide secure connections between vessels, ensuring that hazardous chemicals do not escape into the atmosphere while allowing for controlled reactions. Their durability and resistance to chemical corrosion make them ideal for use in environments where maintaining a vacuum is essential for productivity and environmental compliance.

Challenges and Solutions

In industrial sectors, the implementation of vacuum fittings presents several obstacles. One major issue is the difficulty in ensuring hermetic seals, especially in environments with extreme heat and pressures. Changing conditions can cause materials to stretch or shrink, leading to leaks that negatively affect performance. Additionally, contaminants such as dust and moisture can impact with the quality of the joint, making consistent maintenance and check-ups critical.

To overcome these issues, manufacturers are designing advanced sealing materials that withstand harsh conditions while providing consistent sealing performance. Top-tier elastomers and metal seals designed for specific temperature and pressure ranges can enhance the reliability of joinings in vacuum systems. Implementing enhanced joining techniques, like electron beam joining or braze welding, can also eliminate the potential weak points associated with traditional bolt connections, thereby boosting system integrity.

Another approach involves the integration of consistent maintenance protocols and monitoring solutions that can detect early signs of malfunction. Utilizing sensors to monitor vacuum levels and notify operators to pressure drops can facilitate timely interventions before a complete seal breakdown occurs. By combining high-quality materials with proactive maintenance, industries can substantially improve the performance and lifespan of vacuum flange applications.